What is honing?

- Nagel do Brasil

- May 27, 2024

- 2 min read

Honing is a machining process used to improve the characteristics of the internal surfaces of metal parts, aiming to improve their dimensional accuracy, surface finish and shape. It is frequently used in engine components, hydraulic cylinders, combustion engine cylinders, among others.

Honing Process

During the honing process, an abrasive is pressed and moved against the inner surface of the rotating part. This abrasive removes small amounts of material, improving roughness and dimensional accuracy. Honing is different from simple polishing, as it also aims to correct imperfections in the shape of the piece.

Types of Honing

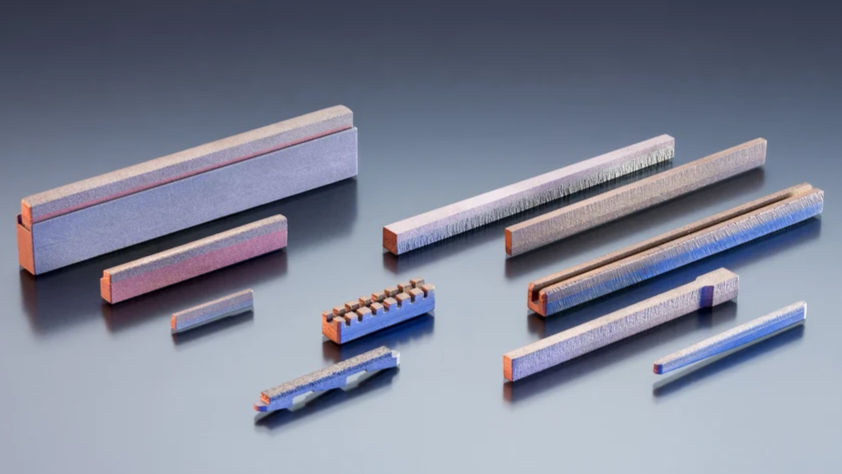

There are different types of honing, each suitable for different applications and materials. Stone honing, for example, uses abrasive stones attached to flexible rods, while diamond honing uses diamond pastes to polish the surface. The process can be manual or automated, depending on production requirements and part specifications.

Honing benefits

Honing offers several advantages. It produces extremely smooth and precise internal surfaces, reducing friction and wear. This is especially crucial in engine components, where efficiency and durability are essential. Additionally, honing can be used to correct ovality and taper, ensuring a perfect fit of parts that require sealing or precise adjustment.

Honing Applications

In the automotive sector, honing is widely used to improve combustion engine cylinders. In hydraulic machines, it is used in cylinders to ensure effective and long-lasting sealing. The process is also applied in medical equipment industries, aircraft and other areas where dimensional accuracy and surface finish are critical.

Modern Honing Technology

With the advancement of technology, honing has become highly automated and precise. Specialized CNC machines can perform honing with high efficiency and consistency, meeting the most demanding specifications. Precise control of parameters such as pressure, speed and type of abrasive allows you to achieve superior honing results.

Conclusion

In summary, honing is a fundamental process in the mechanical manufacturing industry, used to improve the dimensional accuracy, surface finish and shape of internal metal parts. Its application is vast, from automotive engines to precision equipment. With the continued development of honing technologies, this process is expected to continue to play an essential role in modern manufacturing.

Commentaires